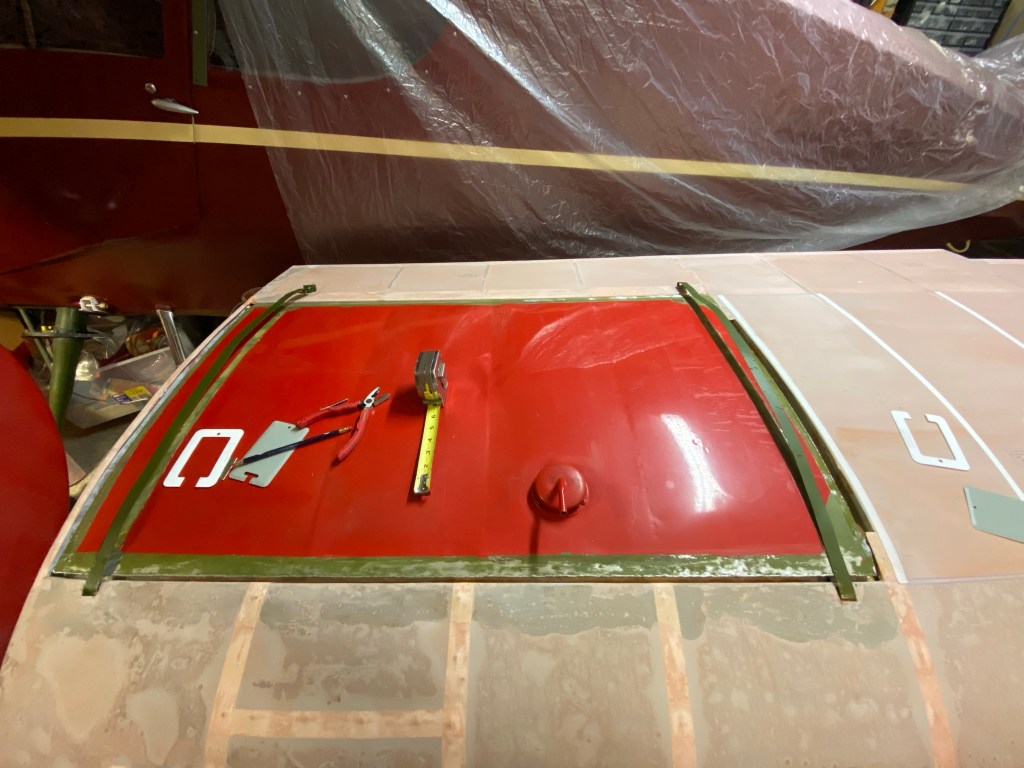

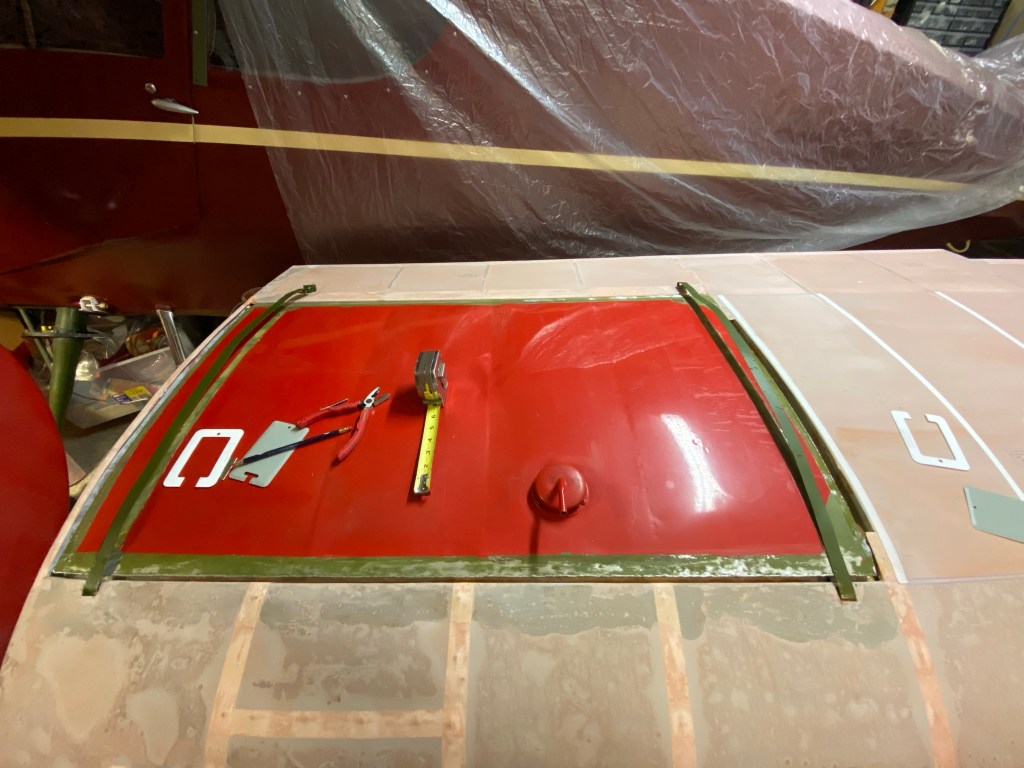

Getting ready to install the wing tank and finish up the tapes and the inspection covers. No fabric goes over the wing tank, just around the edges.

Getting ready to install the wing tank and finish up the tapes and the inspection covers. No fabric goes over the wing tank, just around the edges.

Amazing. You’re the third generation to fix wings like that. Watch that “crazy” glue.

LikeLike

Good point! Hope the fourth generation is interested at some point. I learned from one of your oldest brother’s friends when he had an L-2. Leaned how to rib stitch. Then I did your dad’s Taylorcraft BC-12D wings. Those had Martin Wires so no rib stitching again. Good thing this wing has screws instead of stitching. Goes much faster. It took me one hour to run the reinforcing tape and then the screws on the top side.

Yeah, the poly brush is a smelly product and with just the little bit I’ve been brushing on can really smell up the house. It’ll be much worse when I have to spray on the next two coats on the wing.

LikeLike

Looking good… !

LikeLike

Looks like you’re getting close to putting on the color now, huh? Do you think the “right” wing will go considerably faster, now that you have the necessary experience from the “left” wing? Political “pun” is not intentional !! Ha!

LikeLike

After the tapes and inspection covers, it’ll get two coats of poly brush sprayed on. Then it’ll get three coats of the silver ultraviolet protection coating. Then it’ll be ready for paint. Yeah, sorry, I wasn’t thinking politically when I wrote the post. Port and Starboard will be used from now on.

LikeLike

When I read “left wing progress” I was afraid to open, thinking it was a political statement!

Seriously though I am glad to see it moving forward.

LikeLike

Whoops! Wasn’t thinking politically when I wrote the post. From now on I’ll use Navy terms, so Port and Starboard, instead of left and right 🙂

LikeLike