24S-T and AN-A-13

You see the numbers on the back side of the leading edge of the wing, but what do they mean?

They are material specifications for the aluminum used during the construction of the Stinson. Clad refers to Alclad while the -13 designation refers to aluminum with Alclad. Change that -13 to -12 and you won’t get the Alclad version. Alclad is a corrosion resistant aluminum, first used in the U.S. Navy’s ZMC-2 airship back in the 1920’s.

Alclad used to be a trademark of the Aluminum Company of America, now known as Alcoa I believe.

AN-A-13 is the Army/Navy designation of 24S-T. Apparently they can’t use the same designation as the manufacturing world.

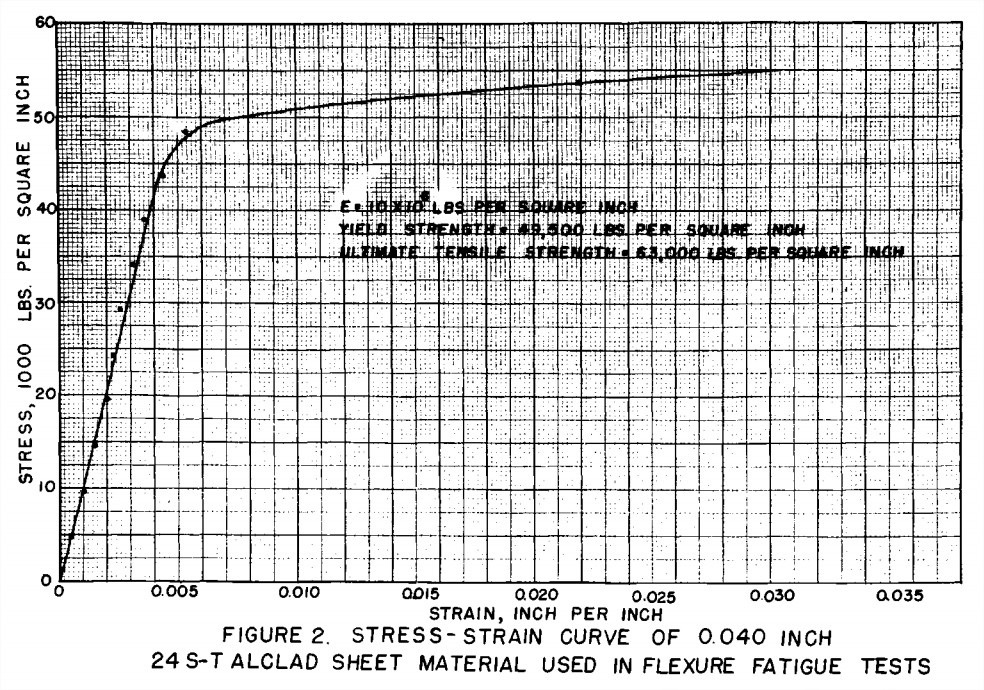

The nominal chemical composition of 24S-T is 4.4% copper, 1.5% magnesium, 0.6% manganese, and the balance aluminum. (Compare that to its replacement composition, 2024T below.) The Alclad 24S-T, which is used on the Stinson, has an additional surface coating of pure aluminum about 10% of the total thickness of the sheet or 5% on each surface.

A 1948 report shows the Alclad version of 24S-T is not as susceptible to surface scratches than plain 24S-T. However, surface scratches through the pure aluminum coating can be an issue. It doesn’t take much to scratch 24S-T, so I have to be careful when using sandpaper or any abrasive product. To remove paint or primer I’ve been using a brush on paint remover where I can.

Alclad 24S-T also affords protection to any sheared edges of the sheets and rivet holes by electrolytic action. What’s that you ask? Basically it’s when two dissimilar metals contact each other. One is the anode (the aluminum sheet) and the other the cathode (could be a wing rib or other sheet of aluminum). Think of it as Republicans and Democrats. They don’t work well together and whenever they are close to each other, it causes problems. It’s best to have something between them.

With the aluminum coating of 10% over the aluminum sheet, that coating functions as an anode, reducing the current flow which causes corrosion. It basically protects the dissimilar metals beneath the pure aluminum from corroding. That’s the idea anyway. If you paint the aluminum with zinc chromate, it protects the soft aluminum from scratches and abrasions when you handle the aluminum. You could also alodine the aluminum, which is better than chromate, but is more expensive. I’ve been using an alodine pen where I can. But they are pricey! See the link.

You could coat the aluminum with Sodium Dichromate, but since it’s use in the 40’s and beyond it’s now known to cause cancer (but you can buy it on Amazon). This chemical will remove any oils and grease while protecting the metal.

One place on the Stinson where you find corrosion by electrolytic action is the steel P-K screws (made from 18-8 corrosion resistant steel) holding the fabric to the aluminum wing ribs or the leading edge of the wing to the ribs. Some of those screws are a pain to remove after 70+ years due to this effect.

24S-T is no longer available. 2024T is its replacement. 2024T consists of 4.3-4.5% copper, 0.5-0.6% manganese, 1.3-1.5% magnesium, and less than a ½% of silicon, zinc, nickel, chromium, lead and bismuth. It is available in alclad sheet form. Compare it to 24S-T and its composition is basically the same.

Rivets

Each type of rivet is identified by a part number so that the user can select the correct rivet for the job. The type of rivet head is identified by AN or MS standard numbers. The numbers selected are in series and each series represents a particular type of head.The most common numbers and the types of heads they represent are:

AN426 or MS20426 – countersunk head rivets (100°).

AN430 or MS20430 – roundhead rivets.

AN441 – flathead rivets.

AN456 – brazier head rivets.

AN470 or MS20470 – universal head rivets.

There are also letters and numbers added to a part number. The letters designate alloy content; the numbers, rivet diameter and length. The letters in common use for alloy designation are:

A – Aluminum alloy, 1100 or 3003 composition.

AD – Aluminum alloy, 2117-T composition.

D – Aluminum alloy, 2017-T composition.

DD – Aluminum alloy, 2024-T composition

B – Aluminum alloy, 5056 composition.

C – Copper.

M – Monel.

The absence of a letter following the AN standard number indicates a rivet manufactured from mild steel.